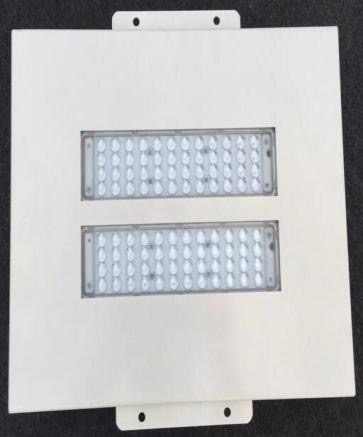

Explosion Proof LED Lights (Explosion Proof)

12 July 2018

Explosion Proof LED Lights (Explosion Proof)

12 July 2018Explosion Proof LED Lights (Explosion Proof)

Explosion-proof is a technique that allows the equipment to be used safely in areas where explosive gases (such as hydrogen or hydrocarbons – methane, propane, etc.) may be present.

Explosion-proof lamps are high-resistance luminaires that can operate in difficult areas. Can be used as spotlight, downlight, low bay, high bay to provide general lighting in dangerous places, such as:

1. Petroleum refineries and service stations

2. Oil and gasoline loading docks

3. Distilleries

4. Paint the manufacturing plants

5. Pumping stations

6. Mines

7. Ships

8. Railways 9. Manufacturing sites 10. High humidity, high temperature or dusty areas

Characteristics:

- Power factor:> 0.95

- Volt: 90-305V

- C / T: 2700-3200k, 4000-5000k, 5500-6500k

- Waterproof: IP65

- Levels of explosion: Exd II BT6

- Certification: UL, CUL, TUV, CB, SAA, CE, RoHS

- Warranty: 3 years.

Minimum quantity: 4

Our Explosion Proof LED Lamps are designed for hazardous areas, where flammable “gases or vapors” are or may be present in the air in quantities sufficient to produce explosive or flammable mixtures. The terms “gases or vapors” make the difference between materials that are in the gaseous state under normal atmospheric conditions, such as hydrogen or methane, and a vapor that escapes from a liquid such as petrol, as well as areas with a high concentration of particles such as granaries, grinders, mines, service stations, aircraft hangars or car workshops and all environments where petrochemical vapors exist.

A vibration-resistant molded aluminum housing prevents the release of sparks from internal components. These explosion-proof LED lamps replace 175 watt metal halide bulbs with comparable output and last 5 times longer. When mounting, a conduit must be used to maintain safety certifications. Can be mounted directly to a pole or mounted to a wall or ceiling using the bracket and conduit.

Explosion-proof means that items that can sparkle are insulated in explosion-proof conduits or boxes that will contain the resulting ignition several times and will not allow it to spread outside the box. To do this, the box must be made of very heavy cast steel with precise contact surfaces and many bolts at the joints with sufficient depth and a minimum gap to extinguish the hot flames below the ignition or to set up seals threaded. The boxes then contain switches, relays and high voltage electrical devices that can operate in hazardous areas.

| Minimum | 4 |

|---|---|

| Model | ECO-NKGS-EP-100W ECO-NKGS-EP-150W, ECO-NKGS-EP-200W ECO-NKGS-EP-250W |